Final offering of equipment no longer needed in the continuing operations of

Crystal Geyser Water Company

Mt. Shasta, California

Facility New in 2015-Never Operated

- Sidel Matrix PET Bottle Blow Molder

- Dry Aseptic Bottle Filling & Label Line

- Tetra Pak Skid Mounted Process Systems

- Unused Stainless Actuator Valves & Pumps

- 30,000 Gallon Propane Tank – 2015 Renovation

COVID-19 Update

Due to social distancing practices to prevent the spread of the novel Coronavirus (COVID-19), inspections and removal of items after the sale will be by appointment only. We are closely monitoring the directives regarding these restrictions and following guidelines from the local health departments.

Sale Highlights

10 Images in this Gallery

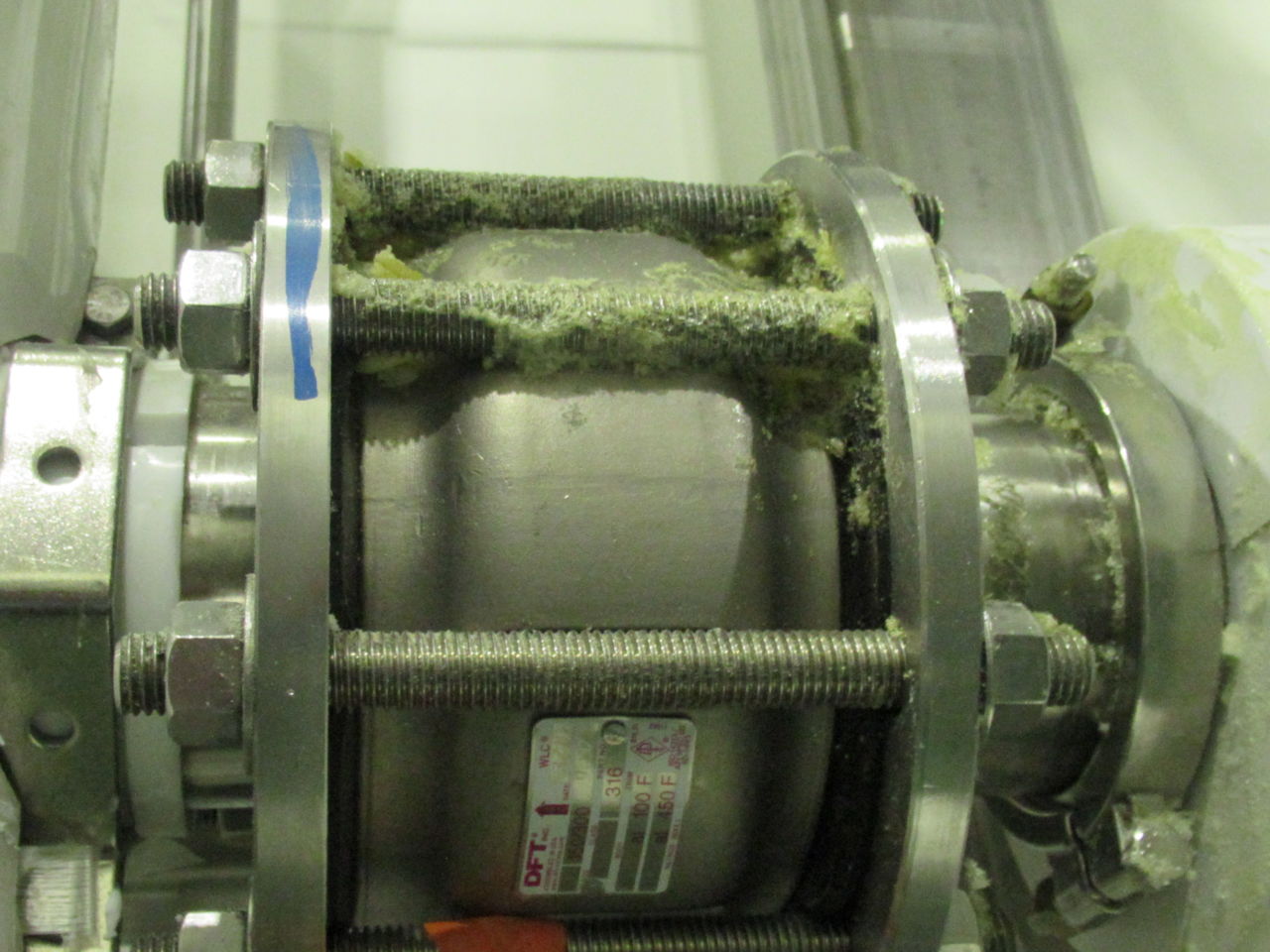

Tetra Pak Skid Mounted Category

- In-Line blending skid for pre-mix juice concentrates with AB plc HD-TFT intuitive HMI unit

- Aspetic Flex continuous UHT treatment skids with header tank, pump sets & metering

- Sterile water generation skid with 500 gal. balance tank, plus tube & shell heat exchanger

- Tetra Aldose carbonation skid for aseptic ingredient dosing with Cartridge filtering & pump set

- Filler interface skid with Alfa Laval-Burkert pnue. control valves and sanitary pipe matrix

- Plus 6000 litre balance tank, assorted Alfa Laval pumps, AB VFD’s, flow distribution manifolds, etc.

10 Images in this Gallery

Blow Molding System

Sidel Matrix PET Bottle Blow Molding System, model SBO-24, 24-cavity, rated for approximately 880 bottle/minute (2200 bottles per hr./cavity). System was commissioned and tested on 1.25-liter bottles but never placed into production. Includes Available with ABC 1200 HP high pressure air compressor system rated for 32 bar (464 PSI), with dedicated chiller and closed-loop cooling tower, conveyorized oven with preform holders, Sidel pre-form feeder with tote dumper, plus mold chiller, inline filters and power modules. Designed to feed Mitsubishi dry aseptic filling and capping system.

9 Images in this Gallery

PET Bottle Filling System

Mitsubishi 120 Valve Dry Aseptic Bottle Filler, model FGR120L36-AS, Setup to run PET bottles of sparkling water & still water and glass bottles of iced tea @ approximately 900 bottles/min.

With 36-head rotary capper, fed by Closure Syst. Inc. (CSI) cap handling delivery system. Available with Heuft Spectrum cap inspector with automatic reject system, Hartness 20′ long stainless table top transfer belt and 90-degree curve to reject accumulation table, plus product water feed system consisting of associated pumps, valves, flow meters, filters, piping and drain system.

6 Images in this Gallery

Labeling Station & Tray Overwrap Systems

- Sidel Matrix PET Wrap Around Rotary Labeler, model SL70, 20-head, currently set up for 500 ml bottles. With change parts for 1250 ml & 12 oz bottles. Available with FT System model IE-720 label inspection system with high-speed air reject and accumulation table

- Hartness Shrink Film Tray Overwrap System, model Global Shrink 4510-80, designed to run 500ml 4x (3×2) packs, 500ml 6x (2×2) packs and 1.25L 4x (3×1) packs. Tunnel is fed by 48″ wide belt with path clearance of 38″ wide x 17″ high. Previously rated at 60 cases/minute.

15 Images in this Gallery

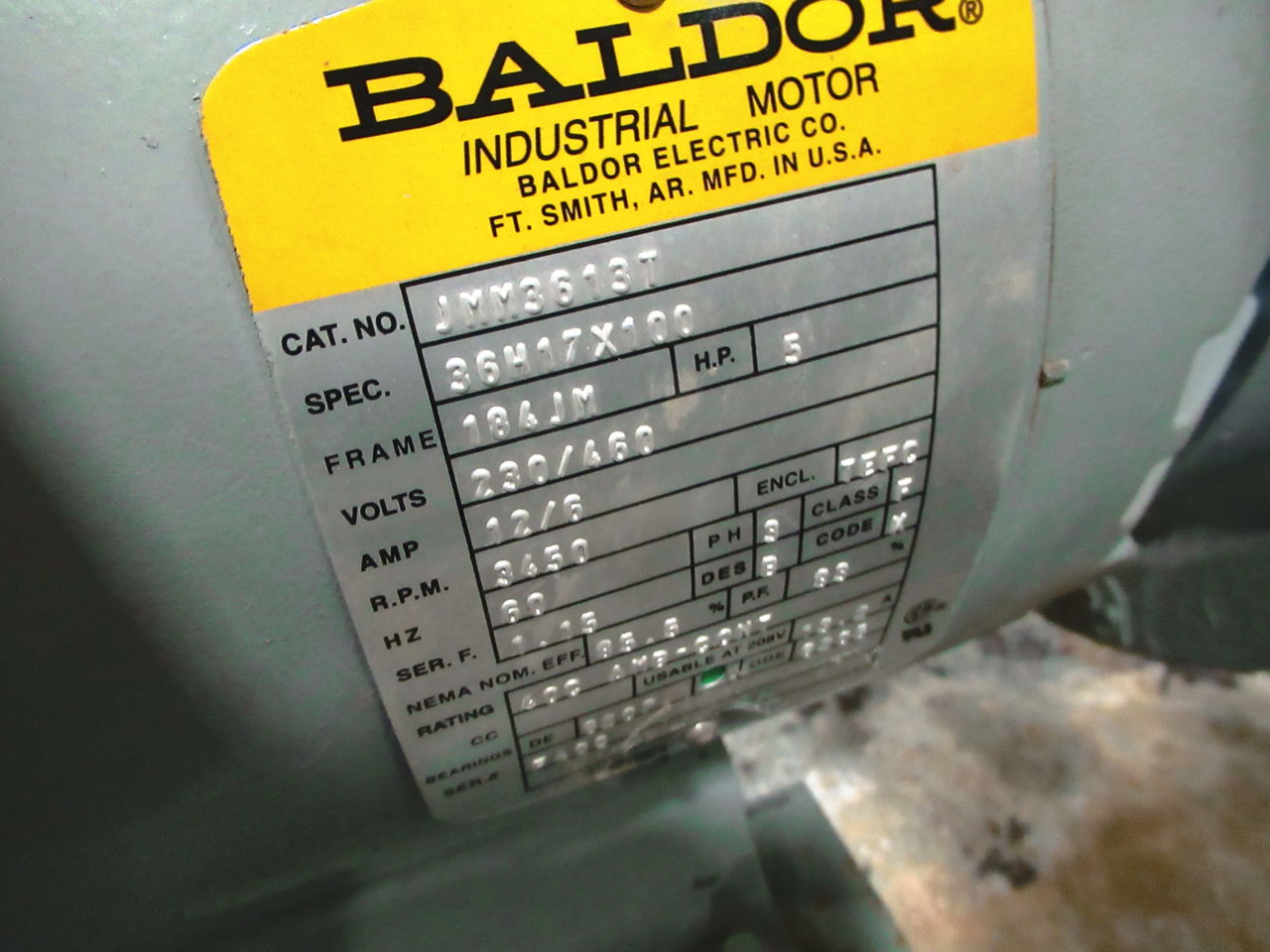

General Plant & Support Equipment

- 30,000-Gal propane tank, 110” dia x 65′ overall, rated for 250 PSI @ 650 degrees F. Renovated in 2015

- Toyota 5000 lb. cap LPG forklift, Northern pallet stacker, Encore floor scrubber & scissor lifts

- Harmony M-30-HD cardboard baler; plus Kpak roll-off hydraulic trash compactor

- Teva RVA 870 evaporative cooling towerl Bry Air dehumidifiers, Vulcatherm temp controller

- Siemens MCC panels, AB 5 door programmable controller, transformers, AB VFD’s and spare parts

- Maintenance tools, welder, pallet shelving, Metro racks, structural steel & aluminum extrusion

14 Photos in this Gallery

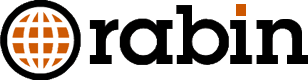

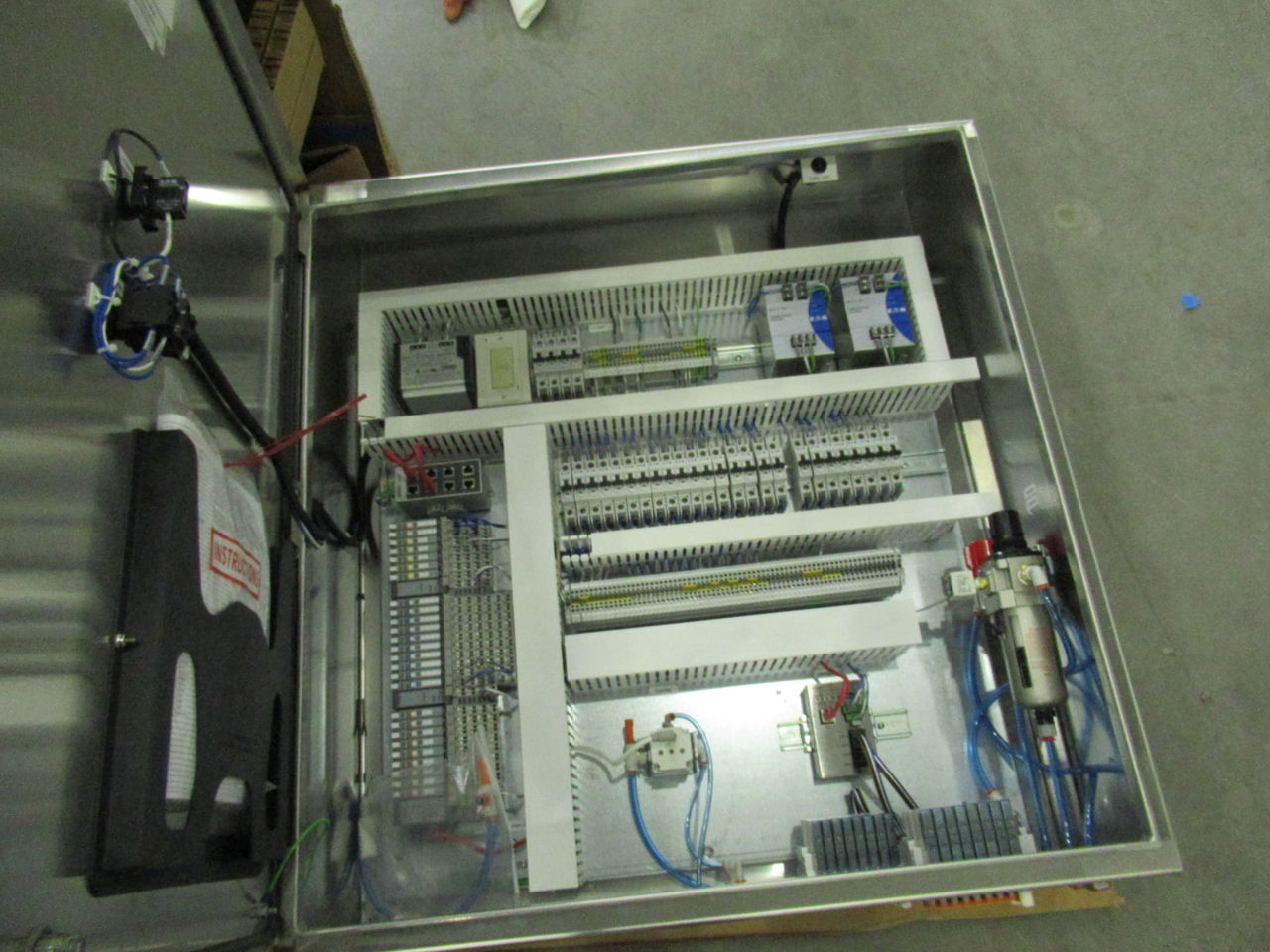

New Valve Acuator Valves, Pumps Flow Metering & Pipework

Large quantity of unused valves, flow meters, and pump sets including: Alfa Laval SSV single seat, and DK-6000 actuator kits and set; Alfa Laval 316SS 7.5 hp pump sets, Alfa Laval CPM1-2W constant pressure modulating valve kits, plus Alfa Laval check & butterfly valves, tri-clamps and assorted sanitary fittings. Endress + Hauser Promag 53H-DN40/50 electromagnetic flow meter sets, Tetra Pak Spiraflow HEX shell & tube heat exchangers and multi-port flow plate; Sanimatic in-line filter blocks; plus stainless butt weld tees, elbows and lots of installed stainless pipework

General Information

For Purchasing Information Contact

Keith Rottman | keith.rottman@rabin.com | 415.248.2007

Inspection by appointment only.

APPROVED RIGGERS

SW Maintenance Corp

Jeremy Ward

Cell: 530-355-2905