Formerly operating as

Stapleton Spence Packing Company

Gridley, California

120,000 sq ft Production Facility

Featuring 6 production lines for:

- Hot Fill Beverages

- Ready to Drink “RTD” Products

- Retort Pouch Filled Products

- #10 Can & Bulk Filled Products

COVID Policy

Out of an abundance of caution for the health and safety of our staff and clients, and to prevent the spread of the novel Coronavirus (COVID-19) and the Omicron Variant, inspections and removal of items after the sale will be by appointment only. We are closely monitoring the directives regarding these restrictions and following guidelines from the local health departments.

Featuring

14 Images in this Gallery

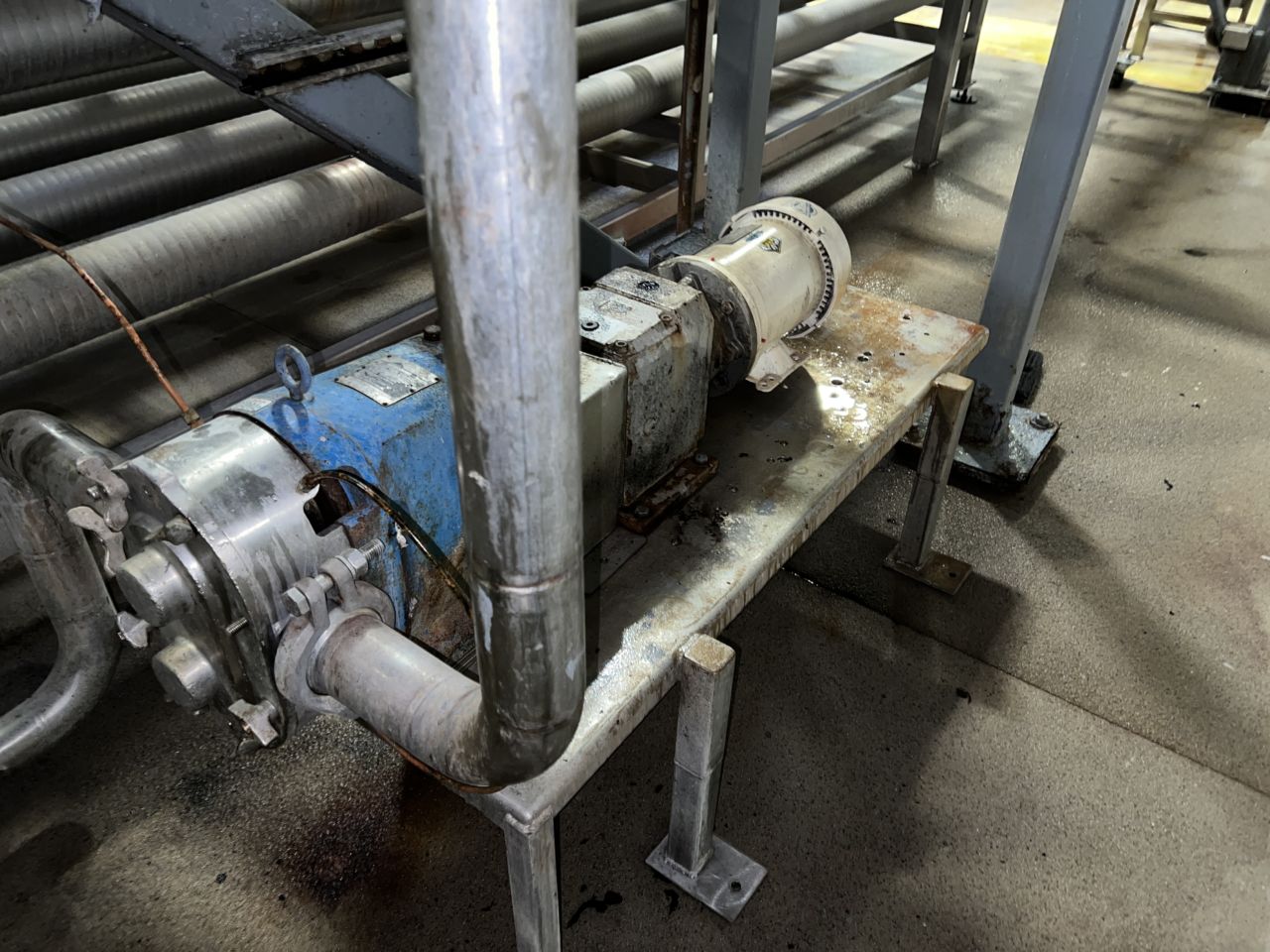

Juice Processing Department

- (14) Process, blend & storage tanks from 500 to 8000 gal.

- Urschel 1500 Comitrol deck with FMC design juice finisher

- Westfalia CA-365 decanter centrifuges with VFD controls

- Aseptic tubular sterilizer with vertical rotovapor column

- Rietz style thermascrew plus stainless pressure retort cookers

- Sweco screens, Waukesha pumps, heat exchanges & more

17 Images in this Gallery

Hot Fill Packaging Line

Partial listing of 2013 installation

- Pacific Packaging 32 head monobloc liquid rotary filler-capper

- Pack West inline spin capper and Whitecap vacuum lug capper

- US Labeling SSL-450 vertical sleeve labeler with steam tunnel

- PE Labelers Futura Top rotary & Quadrel inline labeling systems

- Hamrick drop case packer station with SWF carton erector

- SIM WP-450D tray packing line plus Arpac shrink bundlers

14 Items in this Gallery

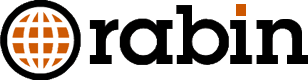

Retort Pouch & Bulk Filling Lines

- Toyo Jidoki retort pouch filler with Ishida 14 head multi-weigher

- Bulk box filling & weighing line with Fortress Stealth metal detector

- Key multi purpose infeed & sorting shakers plus transfer belt tables

- Scholle AF-14-2 aseptic bulk filling system for drums and bag in box

- Mettler Toledo check-weighers, 3M case sealers, Diagraph ink jet coders

- Wide assortment of stainless frame flat and troughing belt conveyors

14 Images in this Gallery

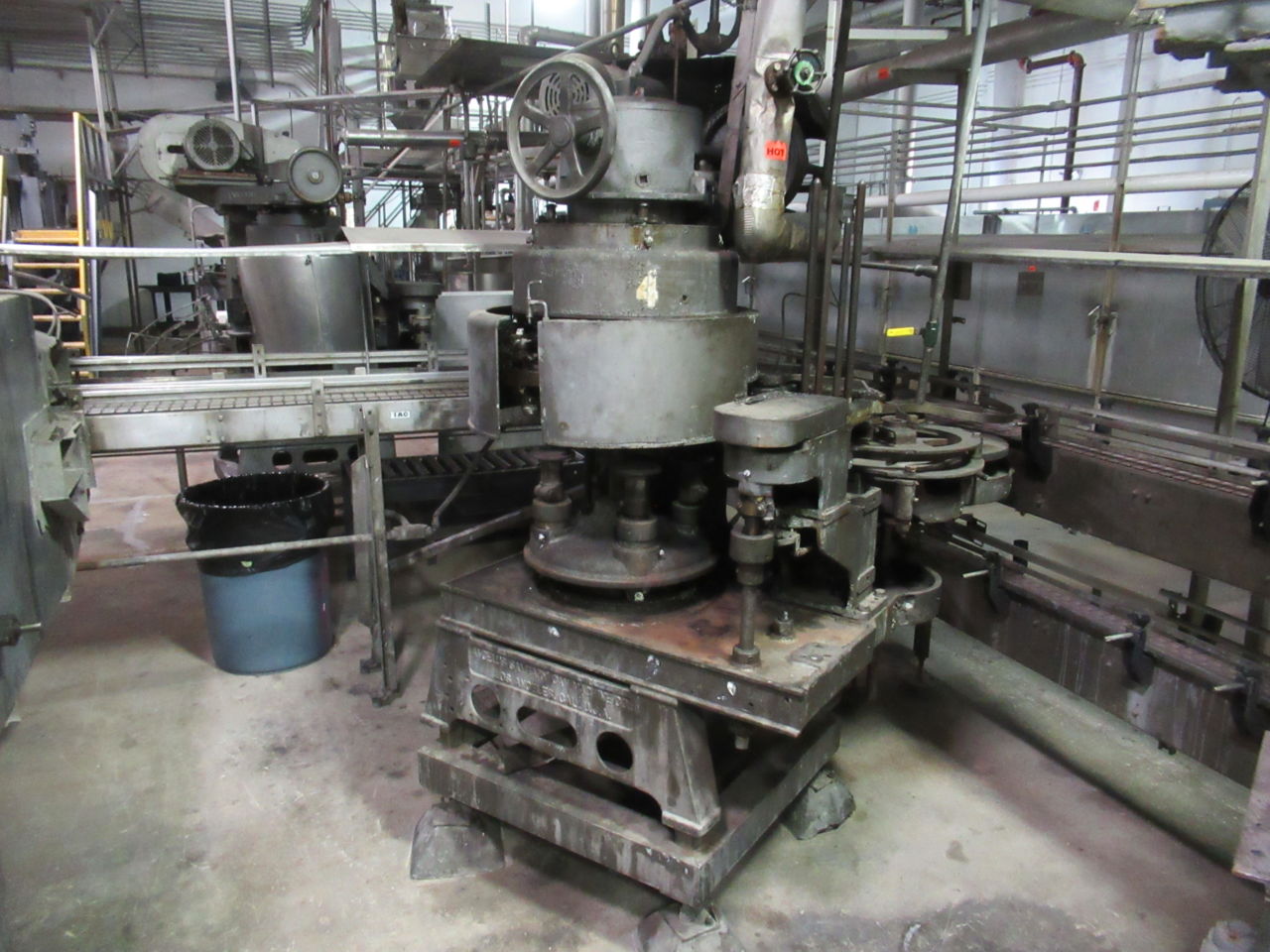

Canning Department

- Angelus 29P & 59P can seamers with can line feeds and discharges

- High Tek multi-head weigher platform with #10 can volumetric filler

- (3) Tunnel pasteurizer boxes including I&H 75’ long x 96” wide sterilizer

- Ramsey Icore checkweigh station with 250+ feet of table top conveyor

- (2) Roll thru labeling lines with Burt labelers & drop case packers

- 3M 700a adjustable case sealers with Marsh Unicorn code daters

14 Images in this Gallery

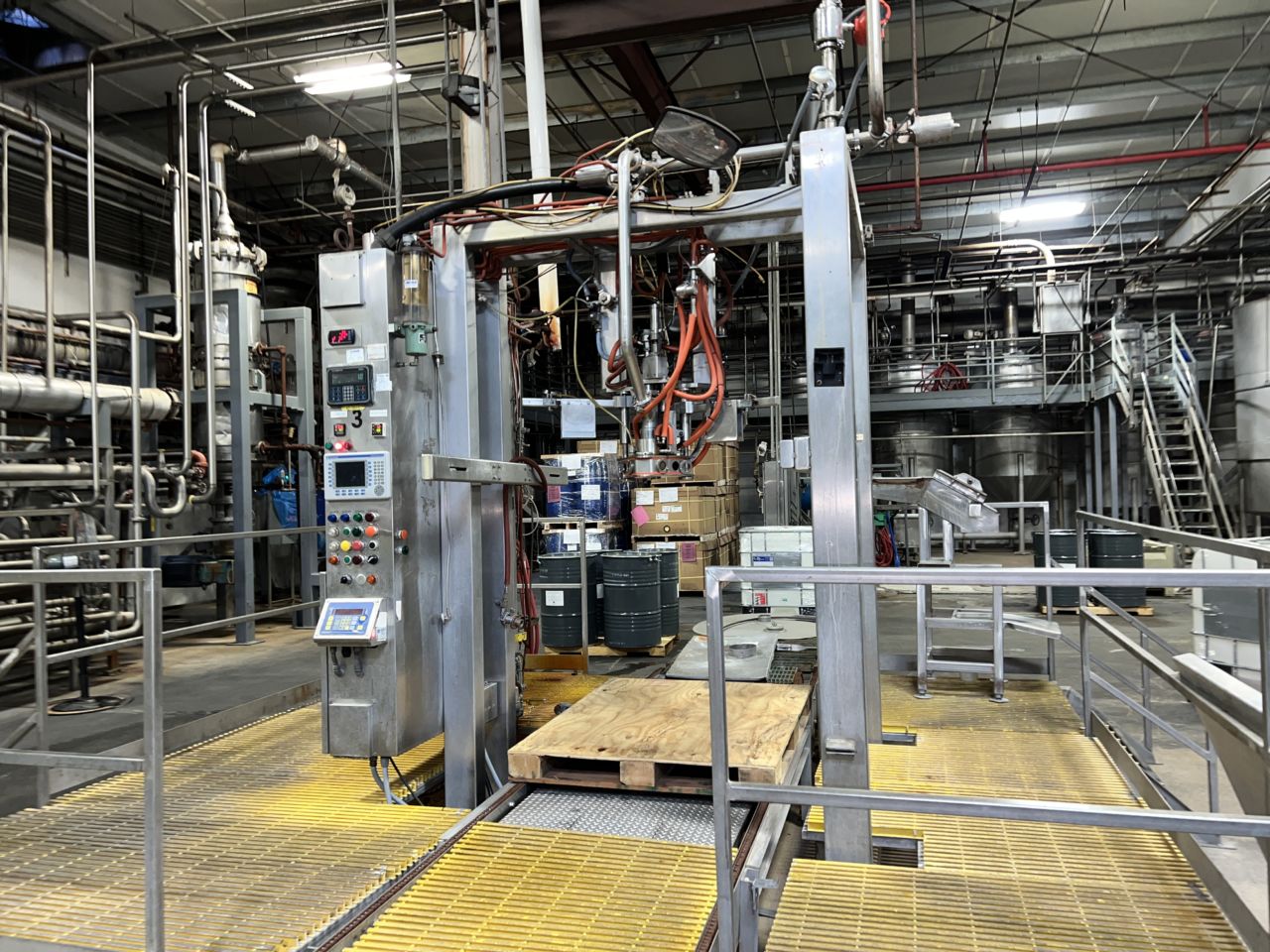

Evaporator, Bulk Storage Tanks & Solar Hot Water System

- Double effect juice evaporator tower with vacuum & water pumps

- (4) 8600 Gallon stainless single wall slant bottom silo tanks

- (4) 3000 to 4000 Gal stainless single wall slant & cone bottom tanks

- Solar water heating system with 8500 gal vertical pressure tank

- Evapco cooling tower & BAC evaporative condenser with pump sets

- Waukesha 130 & 220, plus Ampco and Waukesha CB centrifugal pumps

16 Images in this Gallery

Facility & General Plant

- (2) Cleaver Brooks 400 hp / 200 psi package boilers with deaerator

- Ingersoll Rand R75N Nirvana compressed air system with dryer & filters

- Waste water system with Sweco separator & GR solid waste pumps

- Complete maintenance shop with fabricating & welding equipment

- Advance CS7000 floor sweeper scrubber; complete quality control lab

- (75)+ Sections of adjustable pallet racking plus material handling trucks

General Information

For more information, please contact;

Sam Reese

sam.reese@rabin.com | 415.497.8643