Formerly of Sunergy California LCC

4741 Urbani Ave, McClellan (Sacramento) CA

Total production capacity of approximately 400 MW of

- Passivated emitter rear contact solar modules

- Black Silicon & Bifacial double glass rooftop modules

- Conventional poly & monocrystalline utility scale modules

Featuring Late Model Solar PV Module Production Lines, plus Multi-Million Dollar Raw Material and Finished Goods Inventory.

COVID-19 Update

Out of an abundance of caution for the health and safety of our staff and clients, and to prevent the spread of the novel Coronavirus (COVID-19) and the Delta Variant, inspections and removal of items after the sale will be by appointment only. We are closely monitoring the directives regarding these restrictions and following guidelines from the local health departments.

Highlights

20 Images in this Gallery

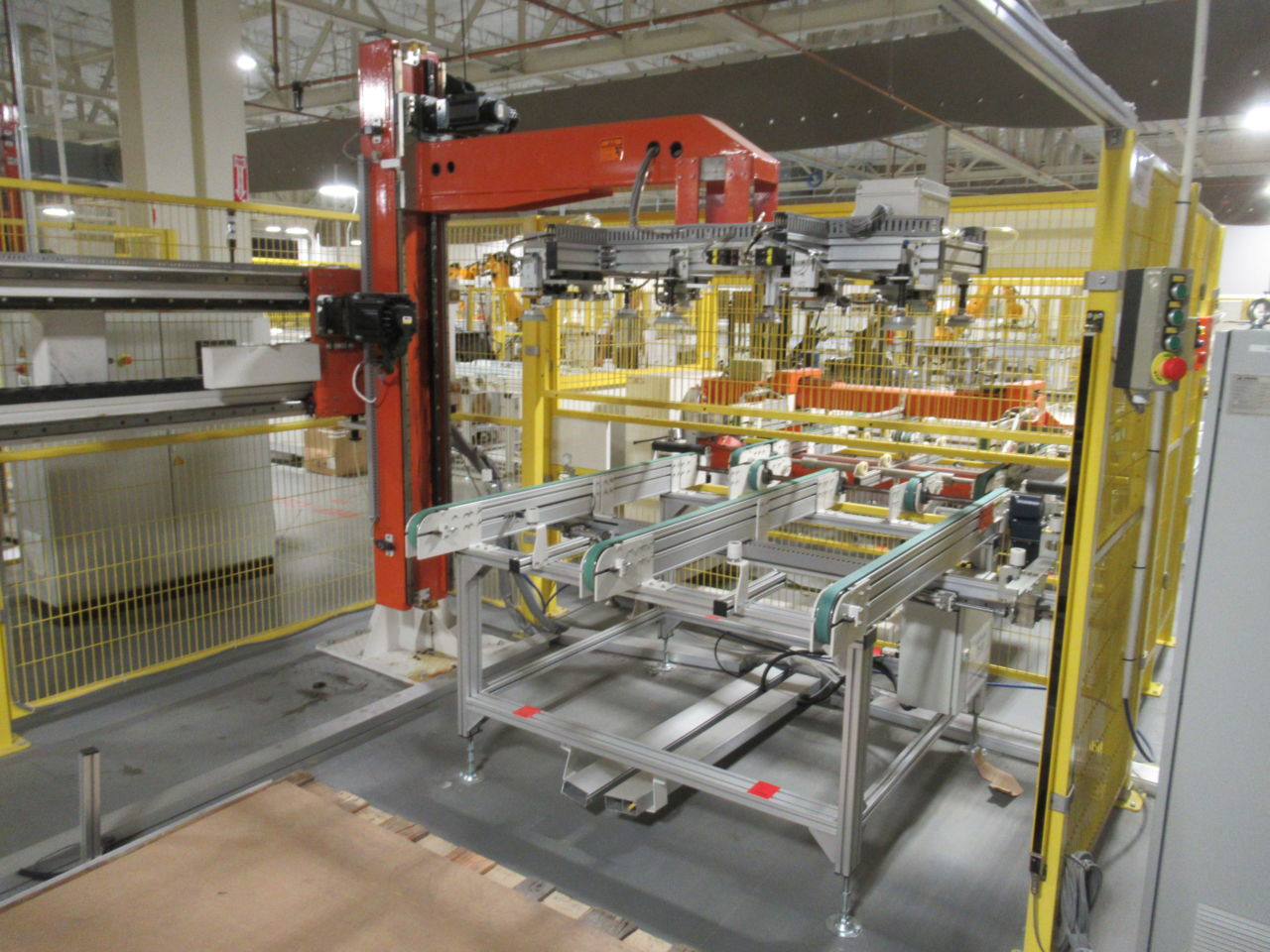

2017 Jinchen Solar PV Production Line #1

Production flow of major components: Robotic glass loading station with EVA auto cutting unit and template placing machine; (4) Jinchen AUSTR-220 auto soldering stations with connecting auto string layup machines; Module auto bussing system followed by (2) EVA/TPT auto cutting and punching machines with shared robotic placing system; Upper air transmission unit with associated lifting stations; Juneng Image auto optical inspection unit and EL tester (2 machines); (4) Jinchen photovoltaic lamination systems each complete with vacuum pumps and temperature control units; Auto trimming station with 90 degree flipper unit; Robotic auto framing station with multiple axis conveyor matrix; Auto chamfering with J-Box semi auto glue stations; Module frame motorized curing belt with (2) robotic loading and unloading systems; HSM single flash large area IV tester with connecting Hi-Pot resistance & EL testers; Finished module robotic sorting & placing system.

20 Images in this Gallery

2018 ConfirmWare Solar PV Production Line #2

Production flow of major components: Robotic glass loading station with EVA auto cutting unit and template placing machine; (2) KFWIV-H auto soldering stations with high speed stringers; ABM-100 Auto bussing system with APT-120 auto taping station; (2) EVA GC-1200 online laying machines; Juneng Image EL/VI testing station; (3) Yiheng Tech 4600-2400 photovoltaic lamination systems complete with vacuum pumps and temperature control units; Auto trim machine with connecting module flipper station; Juneng Image MFAOI secondary test station; Model HGM-120 Robotic framing station with multiple axis conveyor matrix; MTZ type auto polishing machine with EJ-300 gluing station; Motorized curing belt with (2) Estun Robotic load and unload manipulators; HSPV single flash large solar cell module tester with connecting Hi-Pot resistance & EL testers; Model GF-TSB auto labeling station plus Finished module robotic sorting & placing system.

22 Images in this Gallery

Production Support and General Plant Equipment

Main Extraction Line Support Equipment Incudes:

o (3) Automatic 300 litre based centrifuges by Nanjing Kingreat, model PPTD-300

o Mobile & stationary stainless mix and blend tanks ranging in size from 3BBL to 40 BBL

o Assorted size glass reactor systems with speed controller and temp cooling circulators

o HFS vacuum drying ovens, Roto-vapor units, cartridge filter sets, flow control stations

o Liquid nitrogen storage and delivery system with CIDI control room and tanks sets

o Chromatography system, vacuum pump sets, oil bath units, and recirculating chillers

17 Images in this Gallery

Finished Panels & Raw Material Inventory

Finished Solar Panels: Approximately 5000 finished panels as follows: (3200) 390 watt panels, (400) 375 watt panels, (300) 365 watt panels, and (640) 330 watt.

PV Ribbon: approximately 38,000 lbs. of Tellison and Sunby material of 1.0mm x 0.25mm and 6.0 x 0.35mm (additional specs upon request).

Solar Cells: 80,000 Vietnergy 6” x 6” multi-crystalline: 51,000 Ming Hwei 5BB mono SI, P-type big size T175; 81,000 Ureco mono 6 180, 5BB/10.224;

Glass & Back-sheets: 5400 pieces of 3.2mm x 1950mm x 984, and 3465 pieces of 3.2mm x 1976mm x 996 back glass; 2000 plus rolls of SFC, Hannwha & Vistasolar EVA encapsulant and backsheets; (38) Rolls of Coverme Dymat K Laminates.

Additional Raw Materials: Dupont PV 804 white and black photovoltaic sealant, Approx 19,000 Junction Boxes, (40) pallets of Tesa & Darbond double sided foam tape and plastic banding, plus very large quantity of aluminum pre-cut panel frames

General Information

For Information Contact

Randy Small

909.969.1898 | randy.small@rabin.com