Formerly operated by Saputo Dairy Division (Canada)

91 Millidge Avenue

Saint-John – New Brunswick, Canada

At this Sale

- Feldmeir, DCI, Mueller and Crepaco Silos and Vertical Tanks

- Walker Full Sweep Conical Bottom Sour Cream Process Tanks

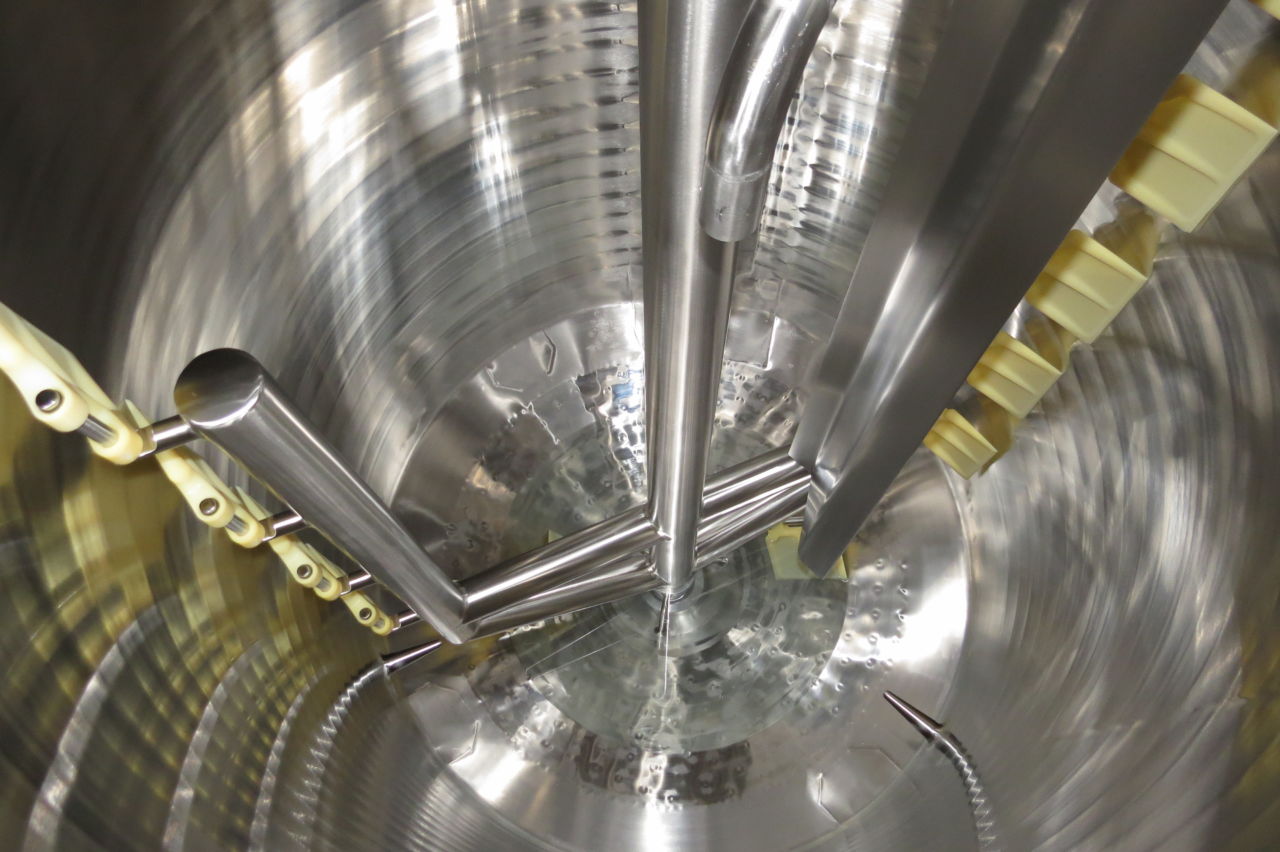

- (2) HTST systems with 2011 Installed Tetra Pak and APV Plates

- Gaulin Homogenizers, Westfalia Separator, APV SPX Plate Coolers

- Fogg 18 head rotary jug filler; Scholle SH bag filler, Canon Milk Caser

- Cleaver Brooks Package Boiler, Mueller Ice Builder, Refrigeration Room

COVID-19 Update

Out of an abundance of caution for the health and safety of our staff and clients, and to prevent the spread of the novel Coronavirus (COVID-19) and the Delta Variant, inspections and removal of items after the sale will be by appointment only. We are closely monitoring the directives regarding these restrictions and following guidelines from the local health departments.

Featuring

14 Photos in this Gallery

Milk Silos & Stainless Storage Tanks

Milk Silos & Vertical Tanks: Mueller & Crepaco 110,000 litre raw milk cold wall storage silos; 95,000 litre raw milk silo manufactured by Tougash, model 2500; (2) DCI vertical milk storage tanks of 31,600 litres (matching s/ns); Feldmeir 22,700 litre vertical milk storage tank;

Horizontal Storage Tanks: (3) Walker horizontal pasteurized milk storage tanks of 8500 & 15,700 litre capacities; (3) Cherry Burrell 13,000 litre horizontal Storage tanks; (4) DCI and other horizontal tanks to 17,000 litres; (2) all stainless 1000 & 4000 gallon horizontal milk tanks

14 Images in this Gallery

Milk & Sour Cream Process Equipment

- (2) Tetra Pak & APV HTST systems both available with Gaulin homogenizers

- Westfalia MSA-160-01-076 automatic self cleaning separator, s/n 1654-416

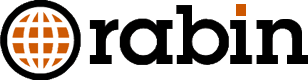

- (4) Walker 1600 litre conical bottom full sweep sour cream tanks, (2008 to 2013)

- (5) Walker & Crepaco conical bottom sweep type process tanks, 1200 to 2500 litre

- APV SPX Paraflow plate heat exchangers available with surge and balance tanks

- Breddo style liquifying blender, automatic CIP valve clusters, plus pumps & pipework

12 Items in this Gallery

Packaging & General Plant Equipment

Milk Filling Department: Fogg 18 head rotary plastic jug filler, Scholle model SH bag filler used for mix products,

Canon milk case packers, stackers & loupe inventers, plus 3 tank CIP system

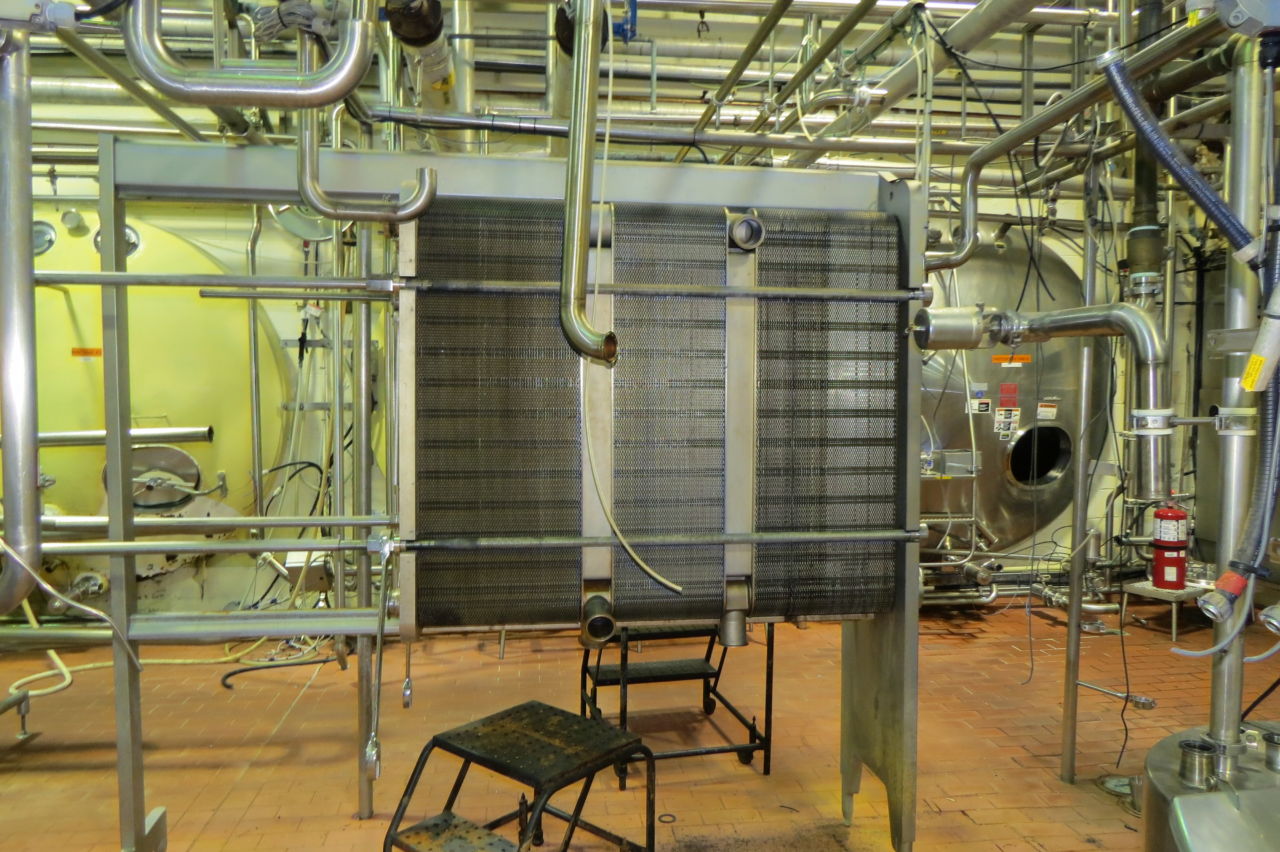

Facility Equipment: includes Mycom and Cimco 100 hp refrigeration compressors, Ice builder, glycol tanks,

Atlas Copco air compressor & dryer, Cleaver Brooks 200 hp package process boiler

General Plant Assets: includes Robopac semi auto pallet wrapper, 300 litre portable aseptic storage tanks,

milk case trolleys, hydraulic power units, warehouse racking, spares & offices

General Information

For more information

Justinian La Rosa

jlarosa@c3.com

514.739.3355 | Ext 244

IN PARTNERSHIP WITH