Secured party sale for Coates Toners

555 Country Club Road, Dallas, PA 18612

Sale to be conducted Online in Real Time

Tuesday, November 5th

starting at 10:00 am EDT

Inspection on Monday, November 4th

from 9:00 am – 4:00 pm EDT

Sale Highlights

Powder Milling & Classifying

Production sequence is as follows: Product from bulk “Big Bags” are transferred to a Jet Mill or mechanical mill, which pulverizes flaked material into powder form. For mechanical milled powder, the size is typically 18 microns. For the Jet Mill process, the size is typically 8 to 9 microns. From milling, product is conveyed to classifiers for trimming. Final classified product is collected in either 55 gal drums from the mechanical process, and 450-kilo blending vessels from Jet Mill process. A partial listing of equipment includes:

- 2000 Hosokawa Alpine milling line consisting of: TFG-630 Toner Fluidized Bed Opposed Jet Mill, type 315-TTSP two-stage classifier with variable speed drive; (2) NAZ600 stainless steel air-mill cyclones; (2) Mikro-Pulsaire classifier baghouse filters, explosion-proof – 10 bar overpressure with pneumatic shakers; Lamson 30 & 100 HP blowers, plus heat exchangers, PLC controls, and drive control cabinets

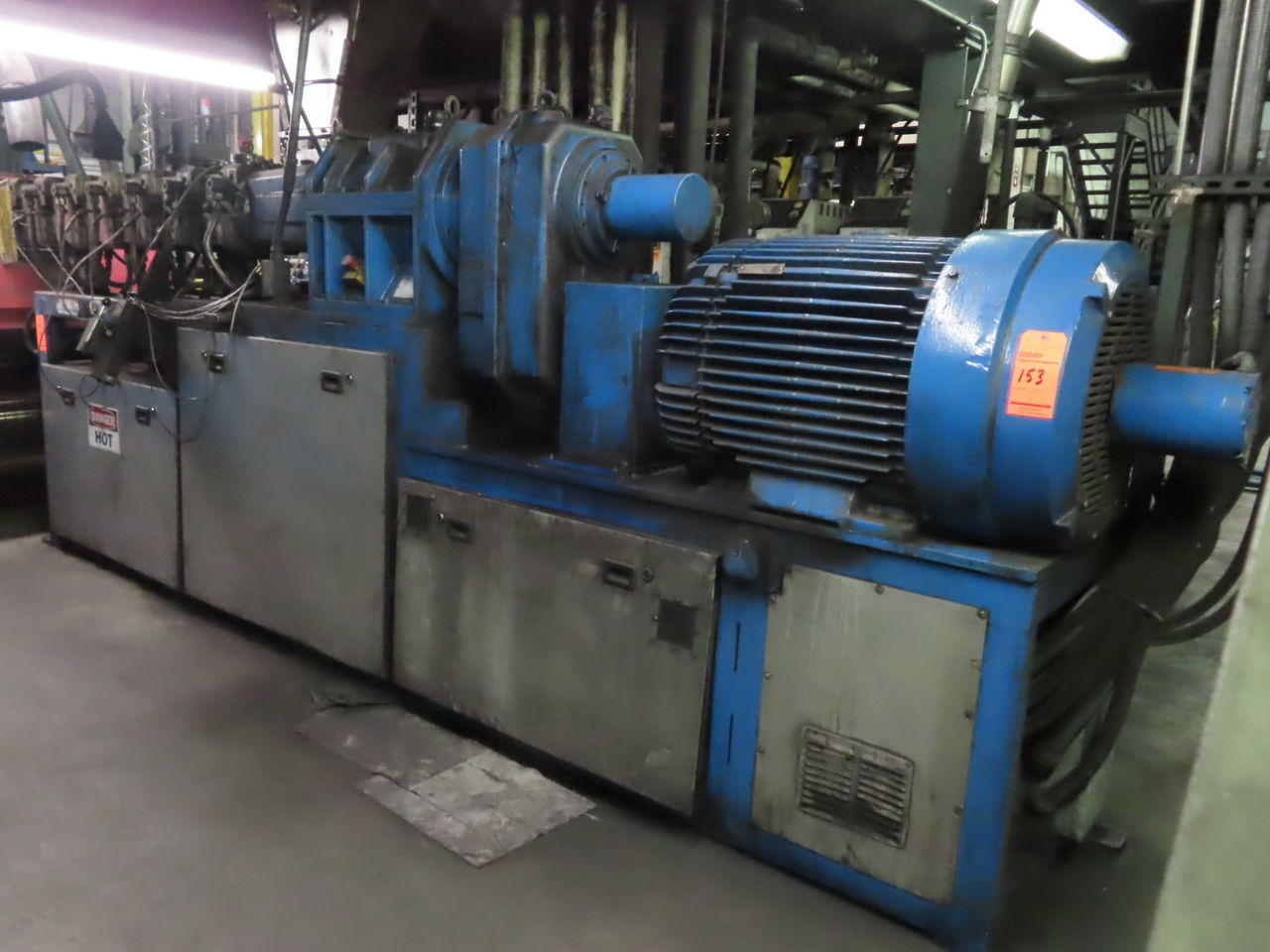

- 1996 Netsch Condux CSM 360/DSF classifier mill, stainless steel/ceramic rotary mechanical mill with 30 HP drive, 10 HP beater drive; Fike explosion prevention system with backflow valve, feed system and bulk bag unloading tower; K-Tron stainless steel weigh cell belt feeder plus K-Tron T-20 side feeder; 2,000 lb. crane system with chain fall

- Classifier line includes: (3) Hosokawa Alpine 200ATP-GS Turboflex ultrafine classifiers, 400 – 4,000 RPM with variable speed drives, explosion-proof to 10 bar overpressure, with (4) Mikropul stainless steel dust collection systems

- 1996 Russell 25120 48″ stainless steel vibratory sieve screener

Mixing, Blending & Extrusion

Raw product batch mixing and blending is typically 250 to 350 Kilo batches. Raw material the mixers homogenize materials prior to extrusion and discharge directly into the extruder infeed. The Jet Mill process requires flow additives which are manually added to the blend or mixing vessels.

- (2) 1996 Mixaco SM600-D 600 liter stainless steel lined 4,500 KG capacity rotary mixers with 100 HP drives and stainless steel feed hoppers

- 2000 Steiger 50 HP inverter mixer with PLC controls, hydraulic raise/lower, plus weigh scale with digital load cells and display

- Netsch Mastermix vertical mixer with stainless barrel, PLC controls, and 50 hz transformer

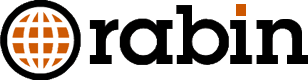

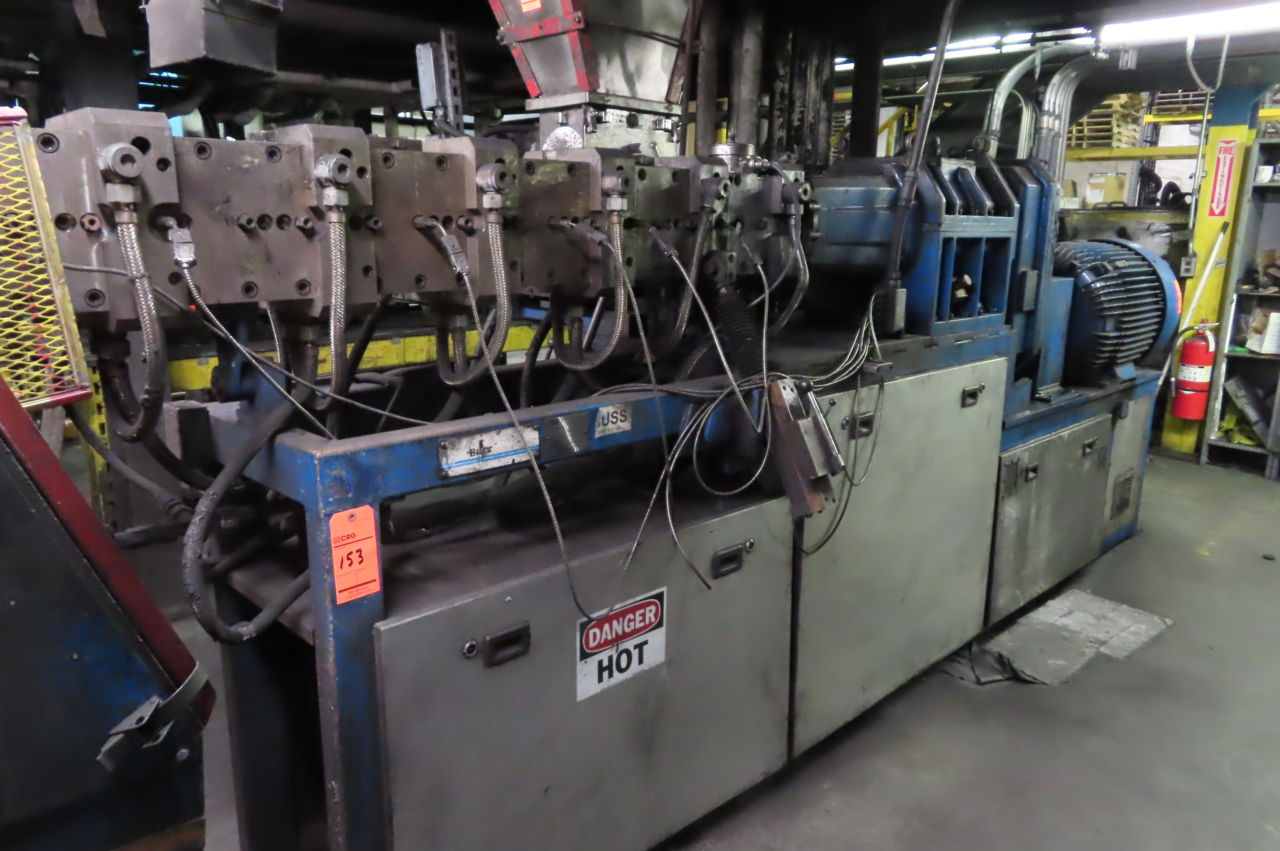

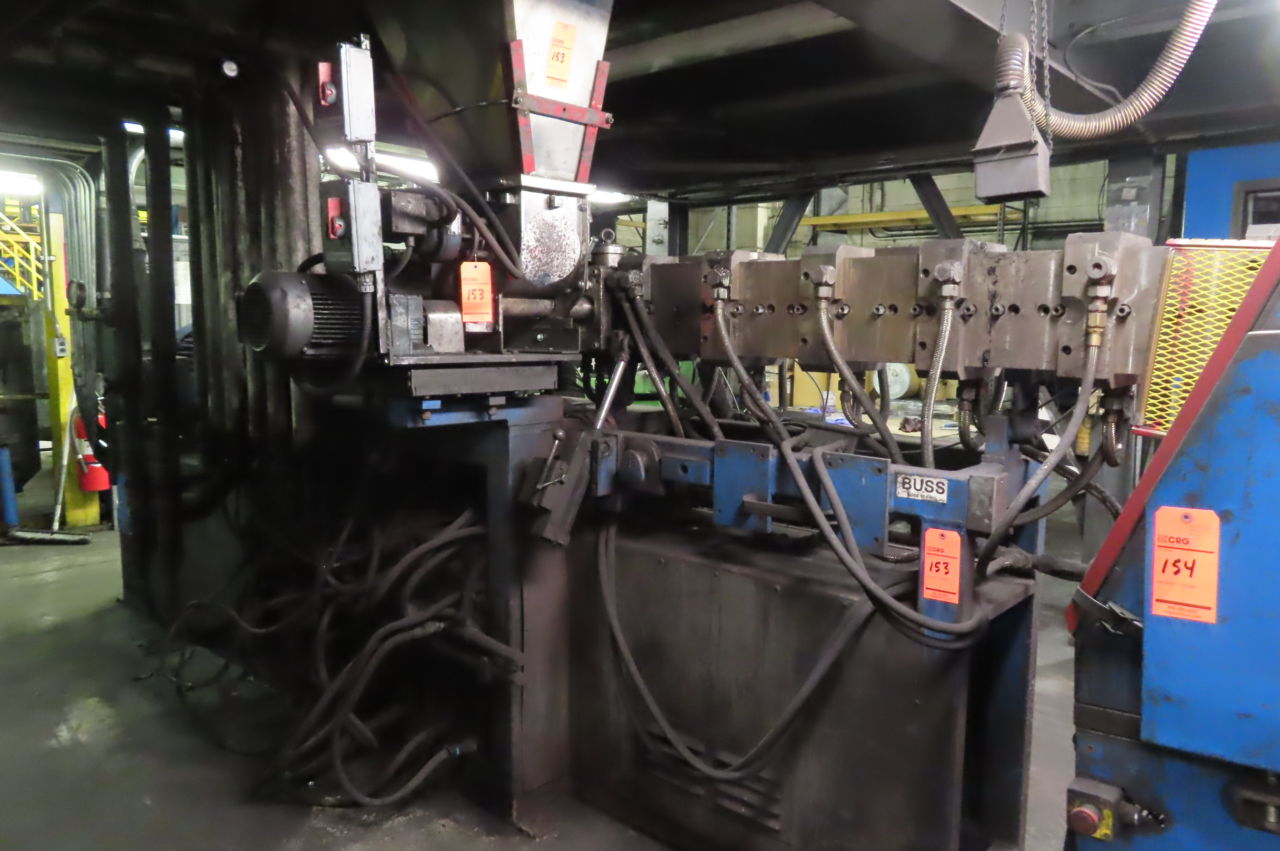

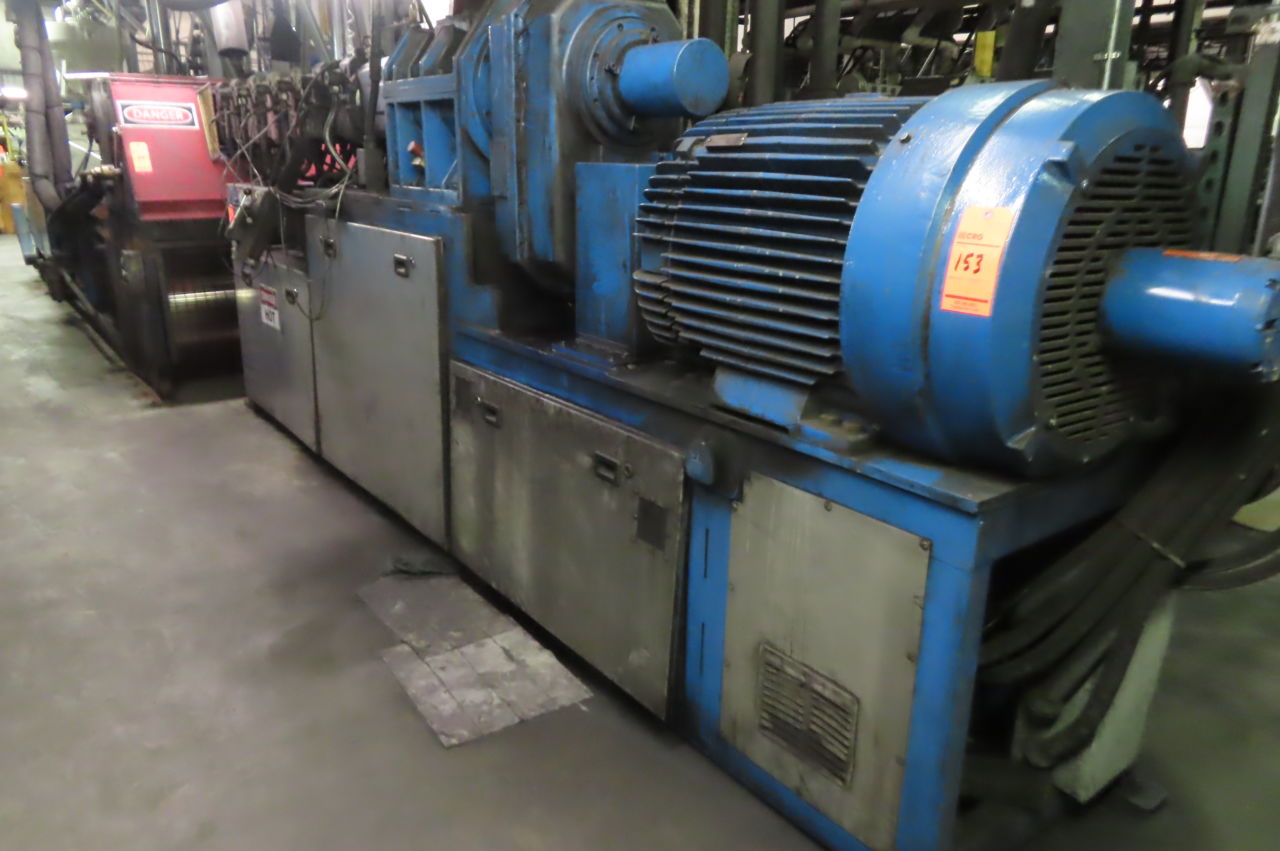

Extrusion lines have temperature profiles along barrels which heats resin materials. The temperature profile is determined by product type and softening points. Extruded product is discharged to chill rolls and cooling belt, then to granulators where the product is flaked. Flakes are then vacuum elevated into fiber bulk bags. Main components of the extrusion lines are as follows:

- 1996 Buss TSC100-16D compound kneader/extruding line, 100 mm 6 section heated barrel extruder/kneader with 125 HP drive, 36″ wide chill roll, 36″ X 15′ stainless steel plate chill table, plus Netzch-Condux pre-breaker/grinder

- 1986 APV MP2065 twin screw compounding extruder, 4-section heated barrel, 65 mm screw diameter, 36″ (w) chill roll, breaker and grinder, retrofitted with ABB PLC controls

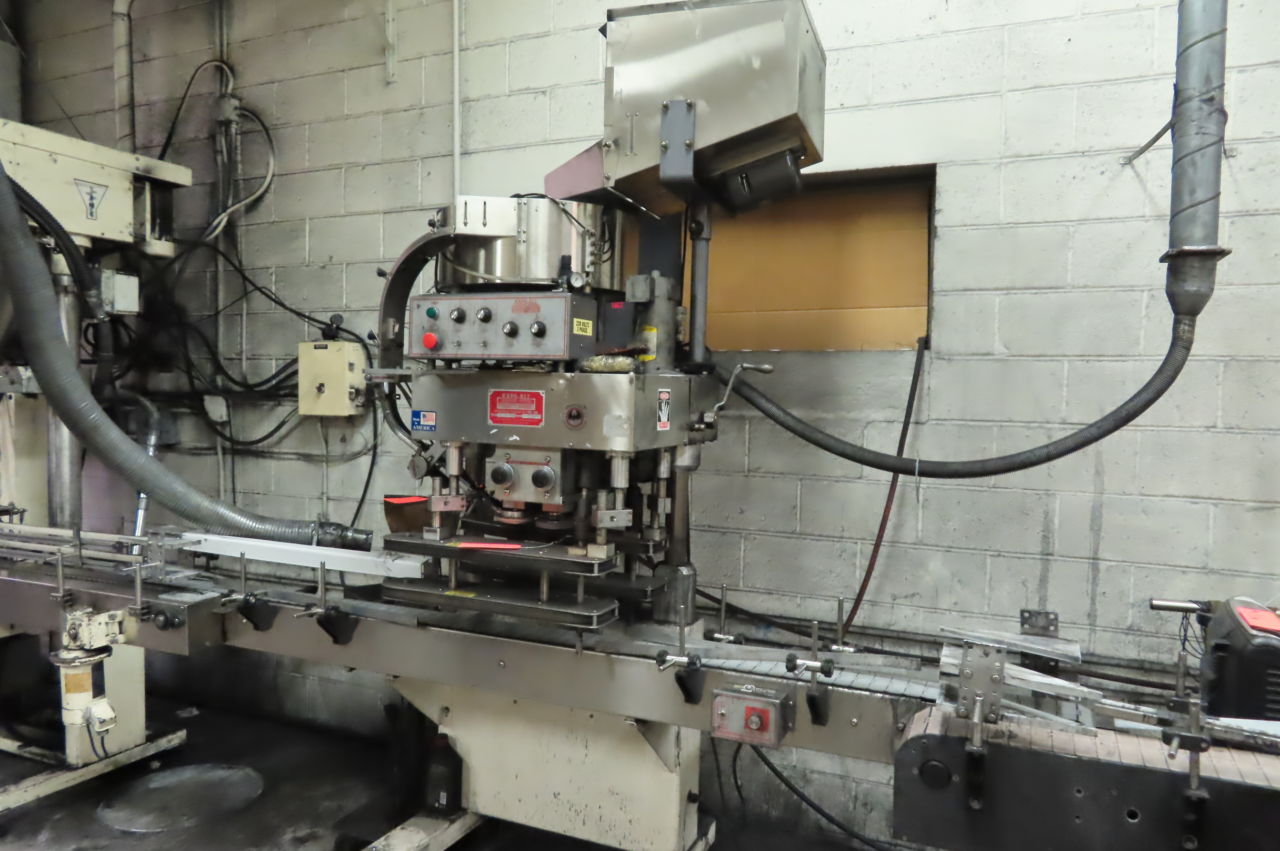

Filling & Packaging Equipment

At end of the blend, extrusion and milled cycles, product is discharged into 100-kilo drums. Smaller finished product packaging is bagged filled into 10 Kilo heat-sealed plastic bags. Following is a partial listing of filling & packaging equipment:

- AMS dual-head bottle filling line, with 36″ stainless steel accumulation feed table, Kaps-All Model E capper, roll labeler, & Little David top/bottom box taper

- Vac-U-Max bulk bag cyclone loader, carbon steel with frame, stainless steel vibratory hopper feed, 5 HP blower

- Bulk bag unloader with 2,000# electric chain fall hoist, pneumatic gate valve, carbon steel hopper and frame

- Cerebus All-Fill stainless steel bag filler with digital weigh cells, pneumatic valves, Cerebus III PLC controls

- Vac-U-Max stainless steel canister blower-bulk filler with tower & 5 HP blower

- Vac-U-Max bulk bag cyclone loader, carbon steel with frame, 5 HP blower

Factory Support Equipment

In addition to the main production and packaging lines, the Coates plant has a wide assortment of stainless mixing vessel, digital floor & table scales, in house fines collection system, plus maintenance shop and R&D laboratory. Major general-purpose plant items include:

- Quincy QSI 500 500 CFM air compressor, 100 HP

- Quincy QSI 245 245 CFM air compressor with IR condensing dryer, oil separator and air receivers

- Ingersoll Rand SSR-EP125 125 HP rotary screw air compressor with refrigerated air dryer

- DCE dust collection systems with pneumatic shakers

- (2) Sterling M2B2010 9 Kw mold heaters with digital displays

- (2) Gorbel bridge cranes with vacuum lifts

- Wide assortment of stainless mixing vessels, digital floor & platform scales, fines vacuums, machine shop & maintenance tools, R&D laboratory, spare parts and supplies

General Information

Coates Toners

555 Country Club Road

Dallas, PA 18612

For more information, please contact

Gary Katz – 1.800.300.6852

gkatz@crgllc.com

Rabin Worldwide – 1.415.522.5700

info@rabin.com

APPROVED RIGGERS

Exclusive Rigger: Carolina Piping and Rigging

Shiro Gartner - shiro@cpiping.com

Cell: 803.428.4510•Off: 763.548.4735

IN PARTNERSHIP WITH

Capital Recovery Group

1654 King Street

Enfield, CT 06082