Formerly operated by

Sesaco

Taylor, Michigan

Plantwide Upgrades in 2021

- Gumus Batch Roasters

- AC Horn 148C Nut Butter Mill

- Moorehouse Cowles Grinders

- Masuko Sangyo Grinding Mills

- Hommak HM20 Homogenizers

Real Estate Available for Purchase

Contact Rabin for Purchasing Information

Further Property Details Here:

6770 Monroe Blvd, Taylor, MI

At This Sale

18 Images in Gallery

Seed Roasting & Cooling

In 2021, the facility installed a new roasting system consisting of (10) individual batch roasters with automation to operate as a continuous batch system. Details include:

- Design production capacity is approximately 2,500 lbs./hr.

- Roasters are manufactured by Gumus (Turkey).

- (12) Roasters were initially installed, with (2) taken offline as spares

From roasting, seeds pass through a Witte USA fluidized bed cooler and stored in stainless silo bins prior to grinding. Entire system is available with plc motor control center

19 Images in Gallery

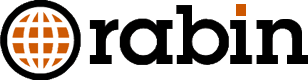

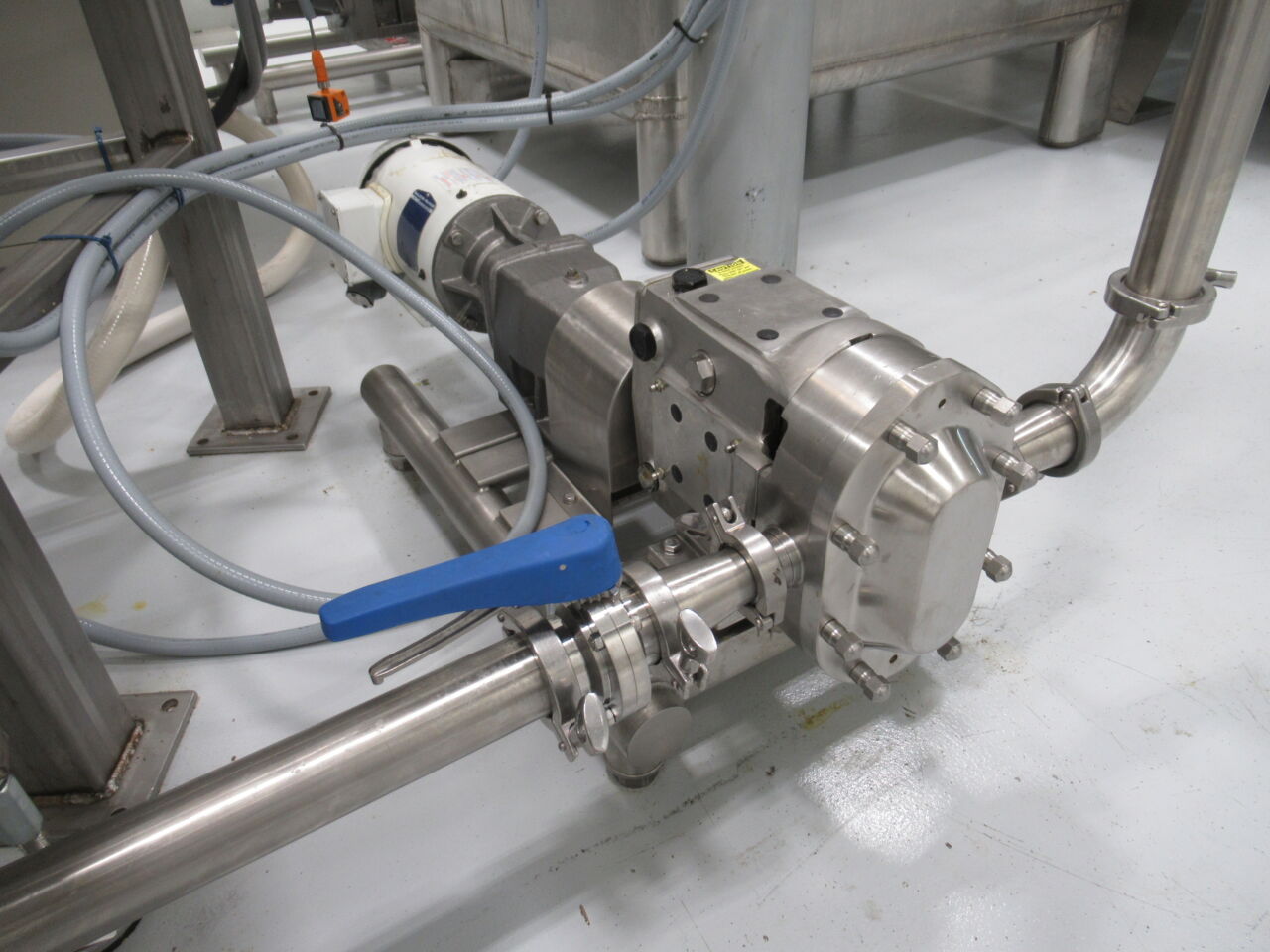

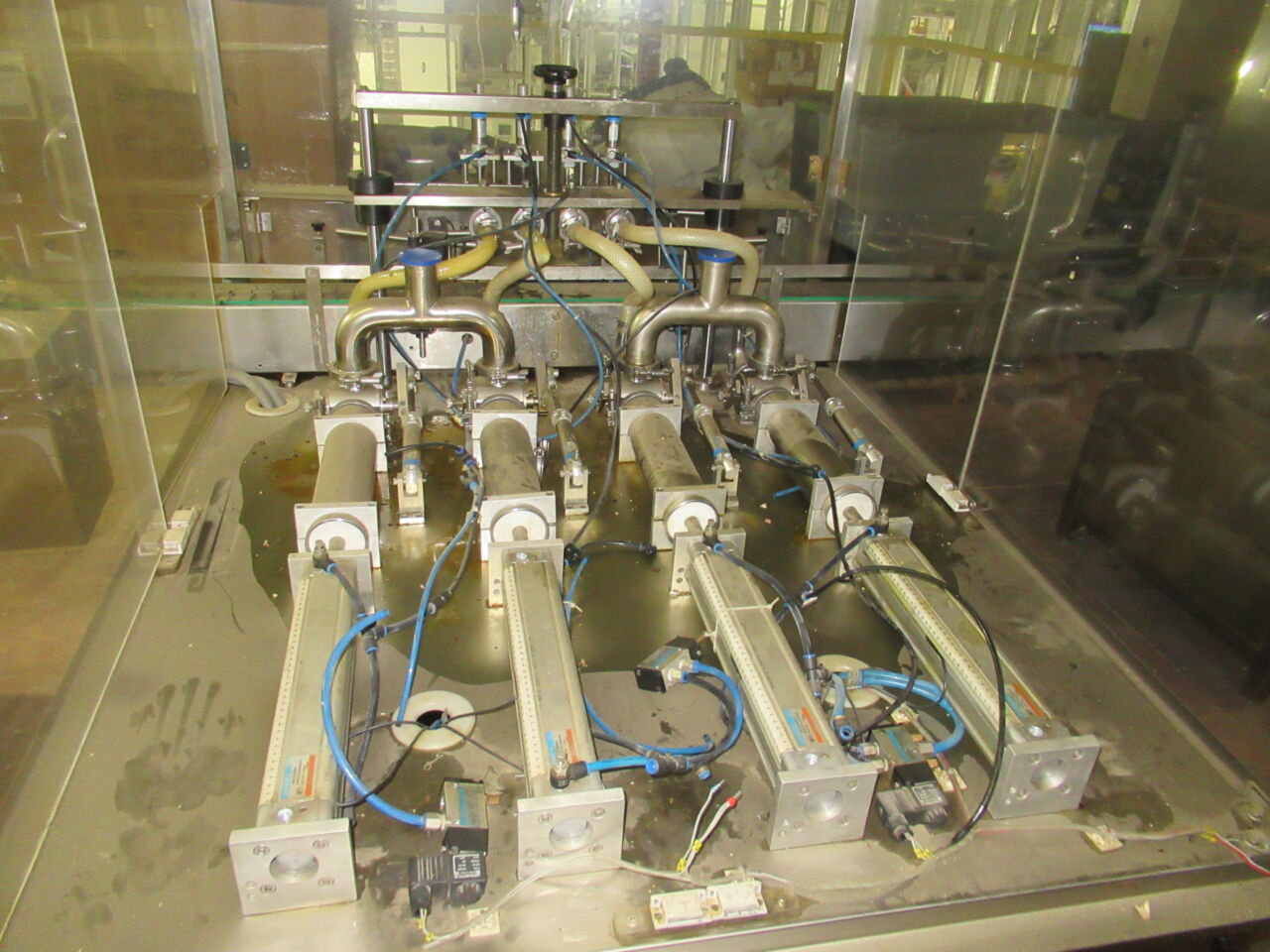

Grinding & Milling

Late model AC Horn, Cowles and Masuku of Japan seed grinders installed in 2021. The grinders are set in a series to achieve a progressively finer particle size, with:

- Design processing capacity of approximately 2,000 lbs./hr.

- (2) Rebuilt Morehouse B1400 grinding mills are part of the process

- (2) Like new Hommak F-HM20 high pressure homogenizing pumps

Prior to 2020, the plant utilized traditional stone mills & Turkish grinders, currently set off line. Ampco positive displacement pumps, plus overhead auger feeders complete the circuit

19 Images in Galllery

Cleaning, Peeling and Drying

Upgraded cleaning and peeling stages of the plant feature a Akyurek (Turkey) EX-2006 seed screener, destoner and gravity table, and 3-stage seed peeling system.

- Cleaning capacity of approximately 6,000+ lbs./hr.

- Peeling stage utilizes air separation of husks achieving minimal water needs

- Full compliment of seed bins, continuous cup and Z-bucket elevators

The stainless drying system was sourced and installed by Akyurek with drying capacity of 1,800 lbs./hr. Final stage features a combined destoner and gravity screening system

18 Images in Gallery

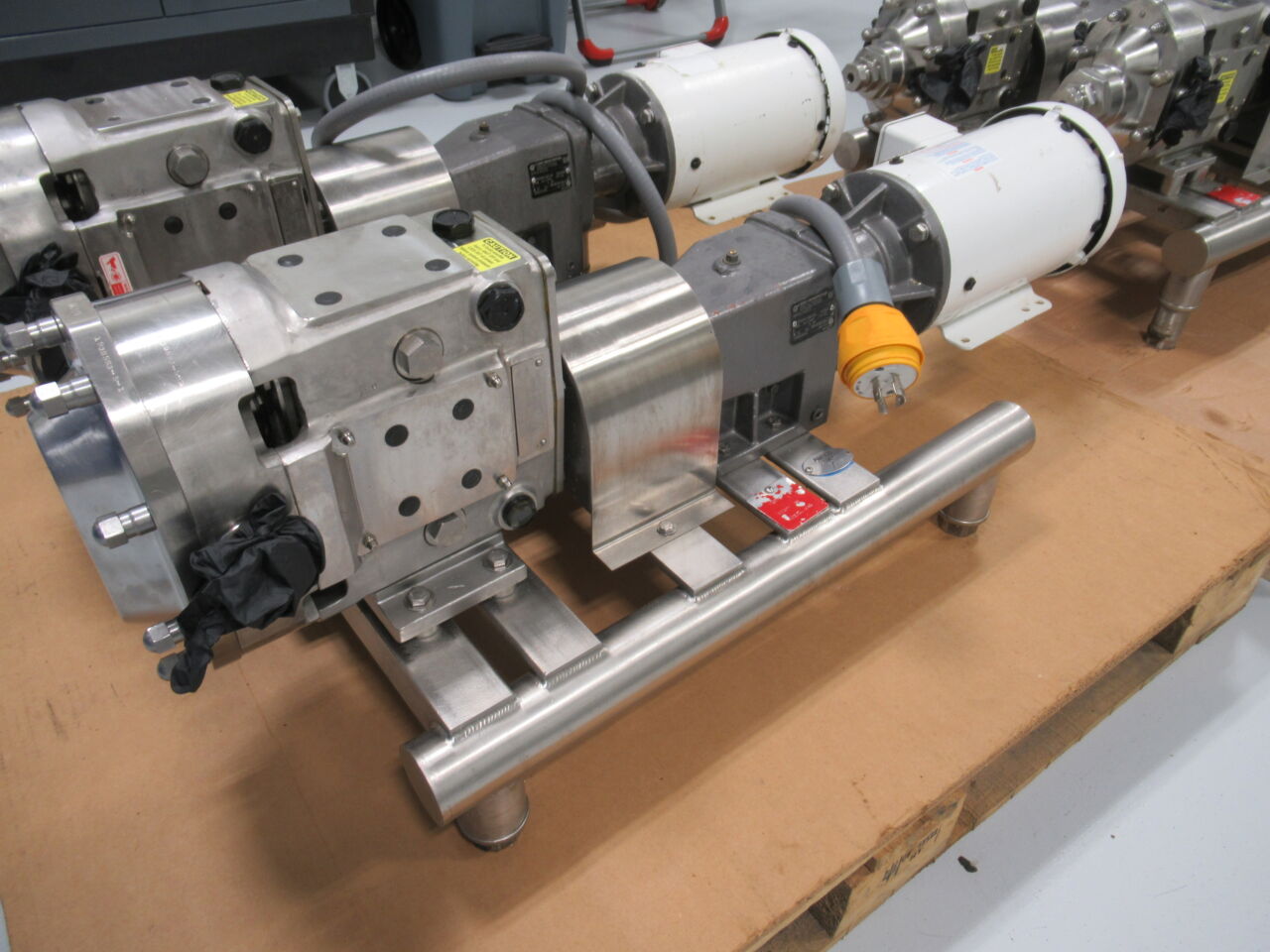

Packaging Department

Within the plant is an enclosed packaging room installation consisting of 2021 installed 5 gallon pail line and Crandall 55 gallon drum filling system. Support includes:

- Eriez Xtreme metal detection system with Sani-Matic filter assembly

- Tran-Store 350 gallon finished product totes with platform scales

- Stainless pipework and valves for bulk filling of Totes (SpaceKraft of IBC)

Also available: New unused 1 lb. paste filling & labeling line complete with unscrambler, single head capper, wrap around labeler, induction sealer & metal detection

18 Images in Gallery

Plant Support Equipment

Majority of equipment purchase new or rebuilt in 2020/21 including:

- Cleaver Brooks CB-700-125-150 psi package boiler, retubed in 2020

- 2022 Electro Steam Co. model LB-150-100 psi steam generation system

- Quincy/ELGI plant compressed air system, 150 psi with dryer & receiver

- Nissan and TCM LP gas cushion tire forklifts, 2,500 to 3,000 lb. capacities

- Robopac model 708-PVS Rotoplat semi-automatic pallet wrapping system

- Quality Insurance Lab with batch roaster & Malvern 3000E particle analyzer

General Information

Equipment & Real Estate Located at:

6770 Monroe Blvd

Taylor, MI 48180

IN PARTNERSHIP WITH